Stronger Gears. Smarter Repairs.

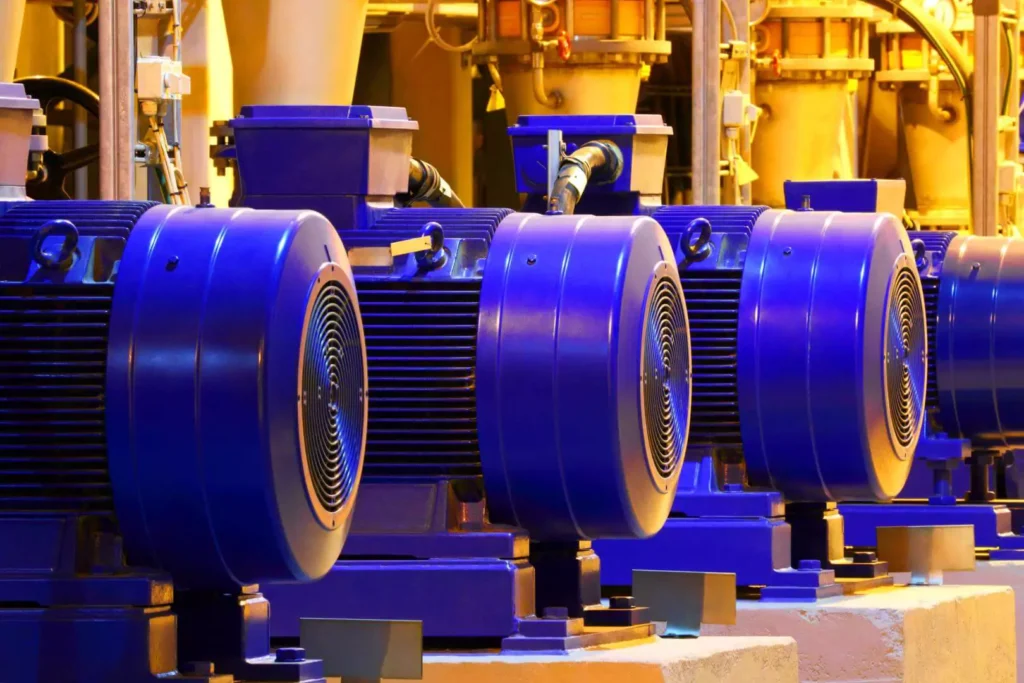

Expert repairs and maintenance that keep your pumps and gearboxes running stronger, longer.

We restore pumps and gearboxes to OEM standards or better, combining expert craftsmanship with advanced technology. The result: longer service life, less downtime, and equipment you can trust in the toughest environments.

Precision Repairs and Reliable Solutions

for Industrial Gearboxes and Pumps

What We Do

At Industrial Gear Works, we specialize in precision repairs, rebuilds, and maintenance services for industrial gearboxes and pumps. With decades of hands-on experience, our team is dedicated to helping businesses in manufacturing, mining, and energy keep their operations running smoothly.

Every job starts with a detailed inspection using advanced diagnostic equipment. This allows us to pinpoint the root cause of issues—whether it’s wear, misalignment, contamination, or overheating—and develop the right repair plan for long-term reliability. From refurbishing gears and bearings to improving lubrication and thermal efficiency, our technicians restore equipment to meet or exceed OEM standards.

We know downtime is costly. That’s why we offer both scheduled preventative maintenance and 24/7 emergency repair services to reduce disruptions and get your equipment back online fast. Our streamlined process includes thorough inspections, clear reporting, and free repair estimates, so you always know what to expect.

Expert Maintenance. Trusted Results.

At Industrial Gear Works, we specialize in keeping industrial gearboxes and pumps running at peak efficiency. From detailed inspections and precision repairs to preventative maintenance and custom gear solutions, our certified technicians deliver reliable results that minimize downtime, extend equipment life, and improve operational performance. Whether you need emergency repairs, routine maintenance, or tailored solutions for expanding or upgrading your systems, we provide the expertise and technology to keep your operations moving smoothly.

WHY CHOOSE US?

Trusted Expertise

Our certified technicians bring decades of experience in repairing and rebuilding gearboxes and pumps.

Complete Solutions

We address root causes, from wear and misalignment to contamination and overheating.

Advanced Technology

State-of-the-art diagnostics and precision machining ensure reliable, long-lasting performance.

Efficiency & Savings

Repairs and maintenance reduce downtime, extend equipment life, and save you money.

24/7 Support

Emergency services and technical assistance are available whenever you need them.

Proven Experience in Industrial Equipment Maintenance

With decades of hands-on expertise, Industrial Gear Works has become a trusted name in industrial equipment repair and maintenance. Our certified technicians specialize in repairing and rebuilding gearboxes and pumps across manufacturing, mining, and energy sectors. We handle everything from routine preventative maintenance to complex emergency repairs, ensuring minimal downtime and maximum operational efficiency.

Using advanced diagnostic technology and precision machining, we restore equipment to OEM standards—or better—while addressing the root causes of failure, including wear, misalignment, contamination, and overheating. Our extensive experience allows us to provide tailored solutions, manufacture custom gears, and deliver consistent, reliable results that extend equipment life and keep operations running smoothly.

Mission, Values, and Approach to Service

Our Mission

To provide precision repairs, maintenance, and custom solutions that keep industrial gearboxes and pumps running at peak performance, minimizing downtime and extending equipment life.

Our Values

Reliability, expertise, integrity, safety, and innovation guide everything we do.

Our Approach

We start with a thorough inspection, identify the root cause of issues, and develop a tailored repair or maintenance plan. Using precision techniques and high-quality components, we restore equipment to optimal performance while maintaining clear communication and rigorous quality testing.

MANUFACTURERS WE SERVICE

At Industrial Gear Works, we provide expert repair, rebuild, and maintenance services for a wide range of industrial equipment. Our team works with manufacturers across manufacturing, mining, and energy sectors, delivering precision gearbox repairs, pump maintenance, and custom gear solutions. We help facilities reduce downtime, improve efficiency, and extend the life of critical machinery. Whether it’s routine maintenance, emergency repairs, or production upgrades, our services are tailored to meet the unique needs of each manufacturer we serve.

Industrial Gear Works

WORK PROCESS

Inspection & Assessment

We start with a detailed inspection using advanced diagnostic tools to identify the root cause of any issues.

Inspection & Assessment

We start with a detailed inspection using advanced diagnostic tools to identify the root cause of any issues.

Precision Repair & Rebuild

Our skilled technicians restore or replace critical components, ensuring every part meets strict performance standards.

Precision Repair & Rebuild

Our skilled technicians restore or replace critical components, ensuring every part meets strict performance standards.

Testing & Delivery

Every repair undergoes rigorous quality testing before your equipment is returned, ready for reliable, long-lasting operation.

Testing & Delivery

Every repair undergoes rigorous quality testing before your equipment is returned, ready for reliable, long-lasting operation.